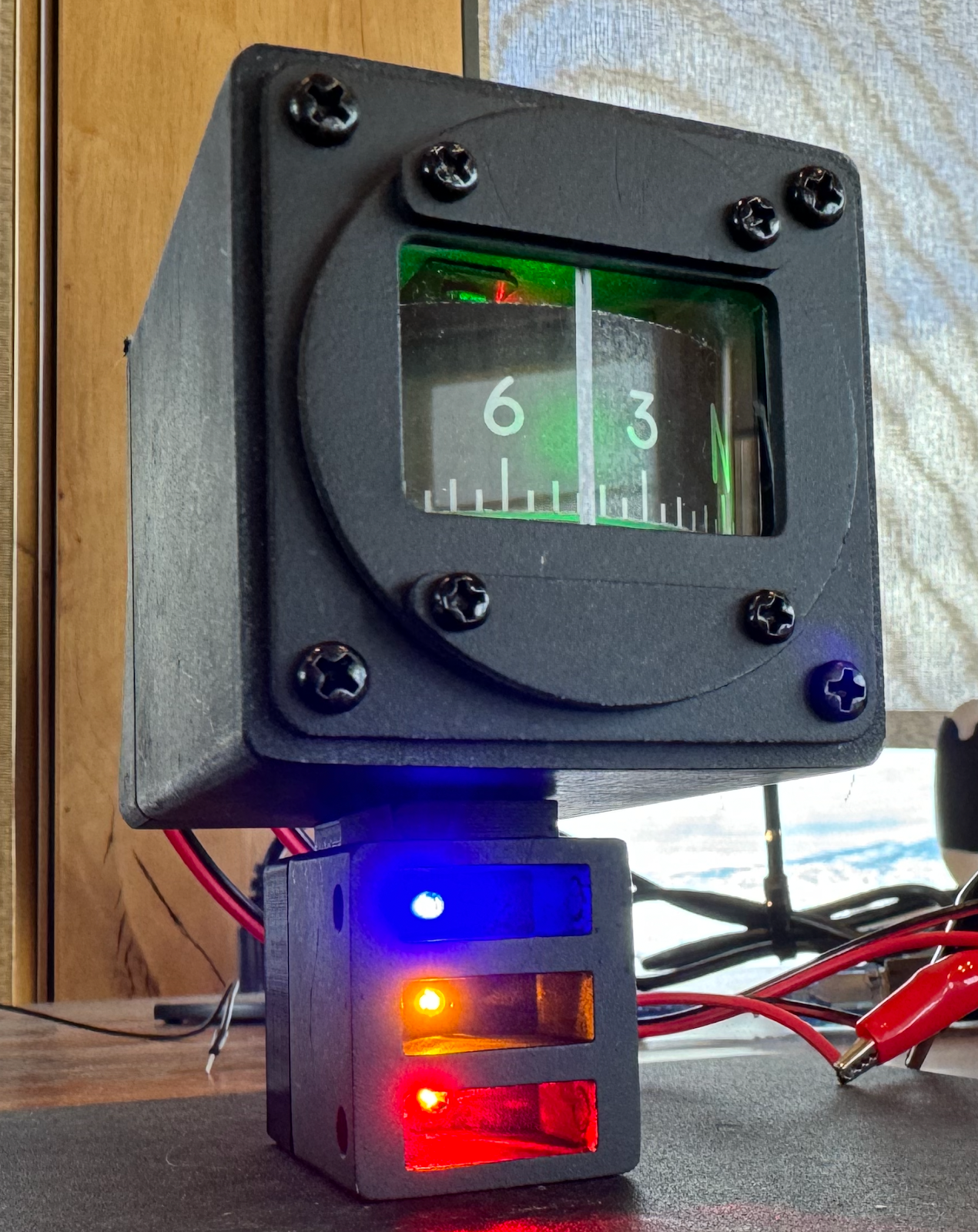

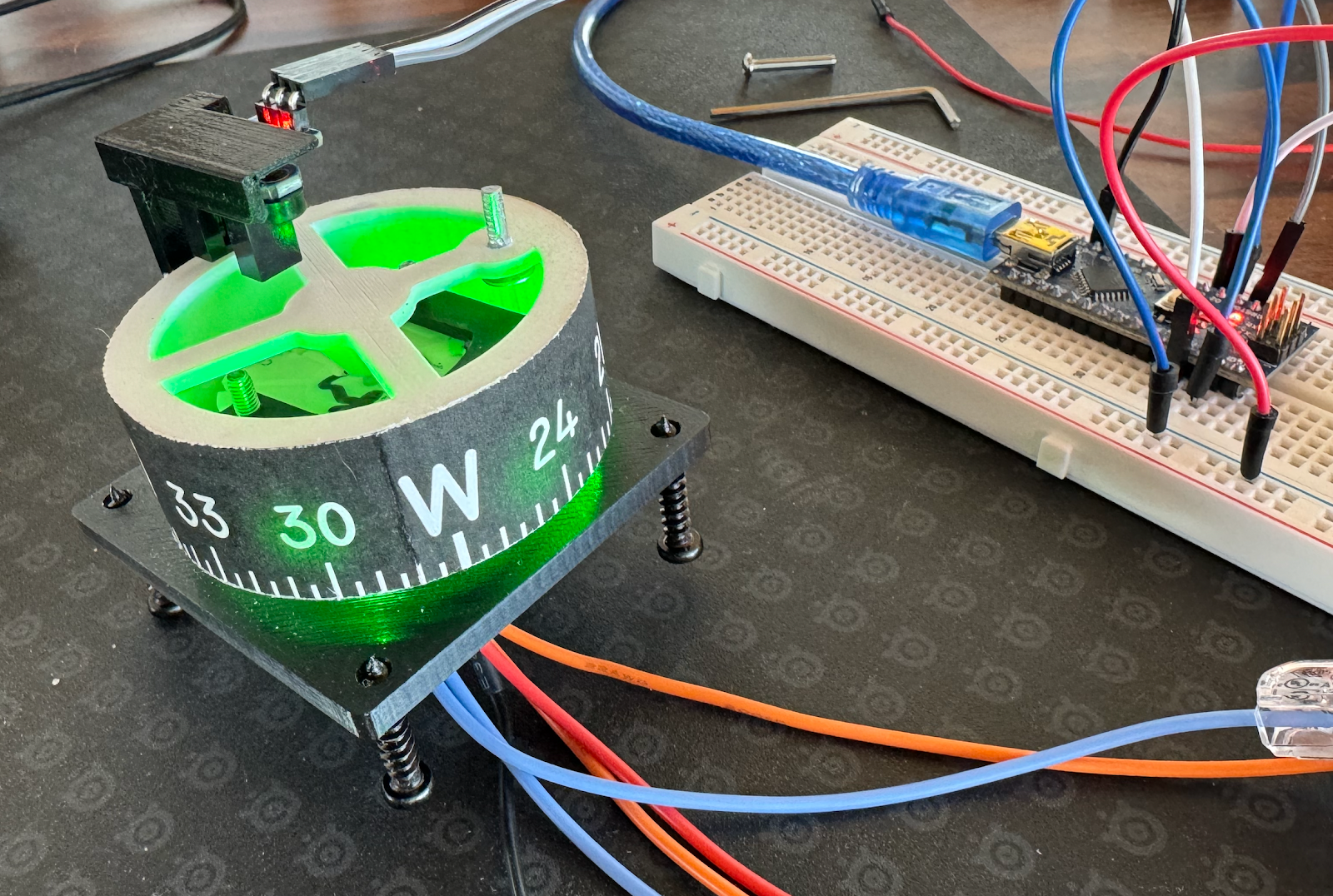

A-10C Standby Compass - Sun Shade

One of the final items to add to this instrument build (besides the text covers for the lower LEDs) was the sun shade for the AR LED box. I made this out of thin aluminum sheets , cutting it from a template using some metal sheers . My template was created by tracing some of the actual artwork from the DCS sim, and then scaling it to the proper size. It turned out ok, not perfect but pretty good. Primed and painted it and then installed it using 2 of the 4 holes that were already on the LED box 3D print. I used some heat inserts in those holes to give the screws something to bite, but the holes are really too big for my inserts so had to use some glue to help out.